research

My group's goal is to offer improved devices and solutions for human health problems by studying the design, materials, and manufacturing of biomedical devices, bio-interfaced electronics, and soft material systems. Vascular diseases are of major interest, including creating implantable electronics for monitoring, soft sensors and actuators for disease models, and soft material platforms to evaluate device designs and surgical procedures. We also focus on the development and use of advanced printing technologies, including robot-assisted controls, to create electronics and soft material systems. Alongside biomedical applications, we study in-space manufacturing and in-space applications for soft functional materials.

manufacturing SMART MEDICAL DEVICES

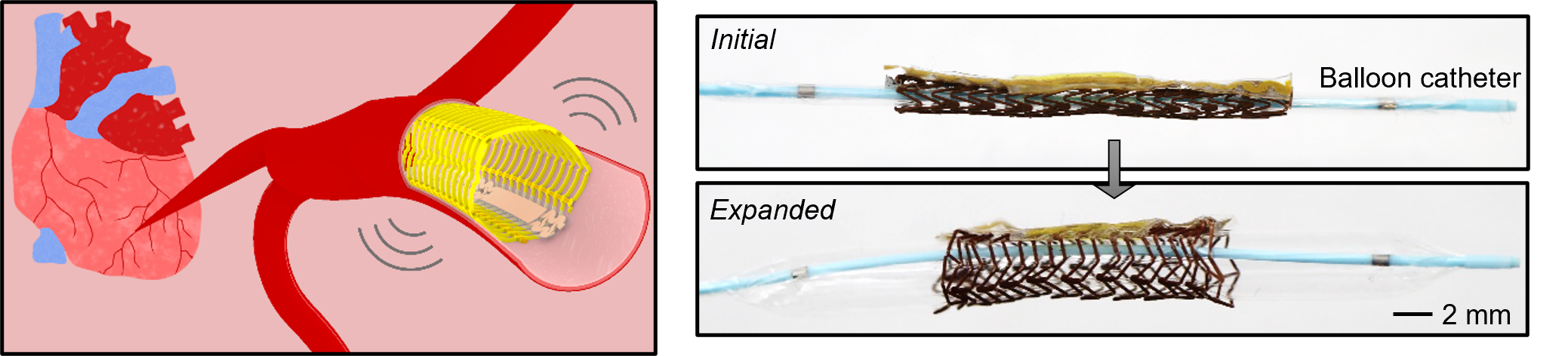

We are interested in developing manufacturing techniques to enable complex, multi-material structures and three-dimensional electronic architectures for biomedical devices, bio-interfaced electronics, and soft robotics. We are focused on adapting existing medical manufacturing technologies (rotational laser machining, wire braiding, and molding) and applying different printing techniques (aerosol jet, inkjet, direct ink writing, and more) to embed electronics and intelligence into well-established medical device structures.

VASCULAR electronics

Vascular diseases account for nearly a third of deaths across the world. By creating implantable vascular electronics, we can provide wireless and unobtrusive monitoring of vascular health and diseases. We aim to replace conventional vascular devices with smart electronic systems for remote sensing and actuation. We are also interested in developing soft electronics and robotics systems for design evaluations of vascular devices and treatments and for use in vascular disease models.

PRINTING SOFT MATERIALS AND ELECTRONICS

Printing offers the ability to pattern a wide range of materials in three-dimensional designs. We aim to harness this ability for bio-interfaced electronics and soft robotics. Included in this work is applying multi-axis, robot-assisted control of printing towards conformal printing and tuning of material systems. Beyond biomedical systems, the printing of electronics is of interest for in-space manufacturing.

WEARABLE electronics

Comfortable, soft electronics interfaced with the skin offer improved health monitoring, diagnostics, treatments, and rehabilitation. We are interested in printing wearable systems, applying three-dimensional structures, and creating patient-specific devices across a broad range of applications.

multifunctional MATERIALS

Soft, elastomeric materials filled with functional fillers, including liquid metal, can mimic biological materials and demonstrate exceptional mechanical, electrical, and thermal properties. We look at developing and characterizing functional materials for soft sensors and actuators.